Le silicone est un matériau très polyvalent utilisé dans de nombreuses industries, Évalué pour sa durabilité, la flexibilité, et résistance aux conditions extrêmes. Différents processus de fabrication façonnent le silicone en divers produits, chacun conçu pour des utilisations spécifiques et des besoins de performances. Les principales méthodes incluent moulure d'injection pour caoutchouc de silicone liquide (LSR) et caoutchouc de consistance élevée (HCR), extrusion, calandrage, moulage par compression, et moulage de transfert. Chacune de ces techniques offre des avantages uniques en termes de précision, vitesse de production, et l'efficacité des matériaux. Comprendre ces processus aide à optimiser la qualité, efficacité, et rentable dans la fabrication de produits en silicone.

Caoutchouc de silicone liquide (LSR) Moulage par injection

Caoutchouc de silicone liquide (LSR) est un bi-composant, Matériau en platine conçu pour les applications de haute précision. C'est fluide, Très résistant aux températures extrêmes, et adapté à la production automatisée.

Processus de moulage par injection LSR

Le processus de moulage par injection LSR commence par le mélange de deux composants de silicone liquide - catalyseur et réticulation - dans une unité de dosage. Ces composants sont introduits dans un mélangeur statique ou dynamique pour assurer l'homogénéité avant d'être pompé dans une unité d'injection. Le silicone mixte est ensuite injecté dans un moule préchauffé à travers une buse sous pression contrôlée. Une fois à l'intérieur du moule, Le matériau guérit rapidement, se solidifier dans la forme souhaitée.

Avantages du moulage par injection LSR

- Cycles de moulage courts et précis, Amélioration de l'efficacité.

- Capacité de production à haut volume, le rendre rentable pour la fabrication de masse.

- Déchets de matériaux minimaux, Assurer une meilleure utilisation des ressources.

- Propriétés de libération de moisissure supérieure, Réduire l'effort post-traitement.

- Qualité constante et haute précision, Le rendre idéal pour médical, automobile, et applications électroniques.

Caoutchouc à haute consistance (HCR) Moulage par injection

Caoutchouc à haute consistance (HCR), également connu sous le nom de caoutchouc durci à la chaleur ou vulcanisant à haute température (VHT) silicone, a un plus épais, cohérence semblable à la pâte par rapport au LSR. Il est apprécié pour sa résistance mécanique et son adaptabilité.

Processus de moulage par injection de HCR

Le processus de moulage par injection HCR commence par du silicone brut, qui est mélangé avec des agents de renforcement comme la silice furieuse pour améliorer la force. Le composé est ensuite préformé en bandes et alimenté dans une extrudeuse à vis, où il subit un mélange intensif et une force de cisaillement pour le rendre uniforme. Le matériau est ensuite transporté dans une cavité de moule chauffée à travers une buse à haute pression. La vulcanisation se produit à des températures élevées, solidification du silicone dans la forme du moule.

Avantages du moulage par injection HCR

- Coûts unitaires inférieurs En raison d'une utilisation efficace des matériaux.

- Déchets réduits par rapport à la moulure de compression.

- Capacité de moulage à matériaux mixtes, combiner du silicone avec des plastiques ou des métaux.

- Excellente précision et stabilité dimensionnelle, Même pour des pièces complexes.

- Adaptable pour diverses applications, y compris l'aérospatiale, soins de santé, et industries automobiles.

Extrusion de caoutchouc en silicone

L'extrusion en caoutchouc de silicone est principalement utilisée pour créer des profils continus tels que les tubes, joints, scellés, et matériaux d'isolation. Cette méthode assure des sections transversales uniformes dans des produits de longue longueur.

Processus d'extrusion en silicone

L'extrusion commence par du silicone HCR brut, qui est formulé avec des agents de durcissement et transformés en bandes ou pains. Ces préformes sont introduites dans une extrudeuse, où un mécanisme de vis rotatif pousse le silicone à travers une matrice en acier durci avec la forme transversale souhaitée. Le profil extrudé est ensuite tiré en continu à travers un four de durcissement à haute température pour assurer une vulcanisation complète. Certaines variations de ce processus incluent la co-extrusion, où plusieurs couches de silicone ou de matériaux supplémentaires sont combinées en un seul passage.

Avantages de l'extrusion de silicone

- Sortie cohérente pendant longtemps, produits uniformes.

- Production à grande vitesse, Le rendre efficace pour la fabrication en vrac.

- Polyvalence dans la formulation des matériaux, permettre des conceptions multicouches.

- Idéal pour flexible, résistant à la chaleur, et composants durables, comme les tubes médicaux et les phoques automobiles.

Calendrier du caoutchouc en silicone

Le calendrier est une technique spécialisée utilisée pour produire des feuilles continues de caoutchouc de silicone avec une épaisseur précise et des finitions de surface. Il est largement utilisé pour produire des tissus et des doublures industriels enrobés de silicone.

Processus de calendrier en silicone

Le processus commence par du silicone HCR brut, qui est chauffé et ramolli avant d'être introduit dans une série de grands, Rouleaux en acier rotatif connu sous le nom de calendriers. Ces rouleaux compressent et étirent le silicone en mince, draps uniformes, qui peut ensuite être renforcé avec des textiles ou d'autres matériaux. Les feuilles de silicone calendantes peuvent également être en relief ou texturées avant d'être guéri dans un environnement de chauffage contrôlé.

Avantages du calendrier en silicone

- Continu, production à volume élevé, Réduire les coûts pour les applications à grande échelle.

- Textures personnalisables et finitions de surface, Améliorer les fonctionnalités.

- Capacité à intégrer les matériaux de renforcement, Amélioration des propriétés mécaniques.

- Idéal pour les ceintures de convoyeur industrielle, films de qualité médicale, et les doublures protectrices.

Moulure de compression en caoutchouc en silicone

La moulure de compression est l'une des méthodes de mise en forme en silicone les plus anciennes et les plus rentables, utilisé pour produire des pièces simples et grandes.

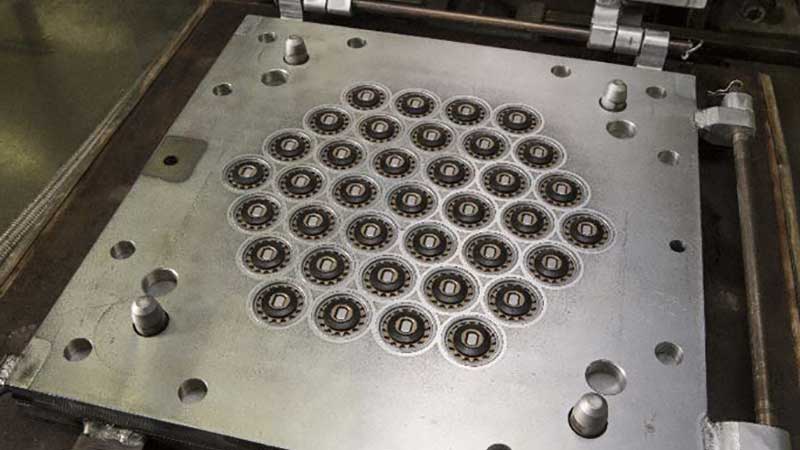

Processus de moulage de compression en silicone

Cette méthode commence par du silicone brut pré-mesuré, qui est placé manuellement dans une cavité de moisissure préchauffée. Le moule est ensuite fermé sous haute pression, Forcer le silicone à se propager uniformément dans la cavité. La chaleur et la pression sont maintenues jusqu'à ce que le matériau remède. Après guérison, le moule est ouvert, et la pièce est supprimée pour la coupe et la finition.

Avantages de la moulure de compression en silicone

- Réduction des coûts d'outillage, ce qui le rend économique pour des courses de petite à moyenne.

- Déchets de matériaux minimaux, Amélioration de la rentabilité.

- Adapté aux pièces grandes ou irrégulières, qui sont difficiles à produire en utilisant le moulage par injection.

- Excellent pour produire des parois épaisses, composants durables, comme les joints automobiles et les claviers.

Moulure de transfert de caoutchouc en silicone

Le moulage de transfert combine des aspects de la compression et du moulage par injection, offrant une précision et une efficacité plus élevées.

Processus de moulage de transfert de silicone

En moulure de transfert, Le silicone HCR pré-mesuré est placé dans une chambre au-dessus d'une cavité de moisissure fermée. Un piston force ensuite le matériau à travers les canaux dans le moule chauffé sous haute pression. Cela permet un meilleur contrôle de débit, assurer une répartition uniforme du matériau dans le moule. Le matériel subit une vulcanisation, Et après durcissement, La pièce finie est supprimée.

Avantages de la moulure de transfert de silicone

- Réduire les coûts d'outillage par rapport au moulage par injection.

- Précision et consistance plus élevées que la moulure de compression.

- Capable de produire des pièces renforcées ou multi-matériaux.

- Convient pour les applications de surmouleur, combiner du silicone avec d'autres matériaux.

Conclusion

Le processus de fabrication en silicone varie en fonction des exigences du produit final, y compris la forme, propriétés mécaniques, et volume de production. Moulage par injection, extrusion, calandrage, moulage par compression, et moulage de transfert chacun offre des avantages uniques, faire du silicone un matériau très adaptable pour les industries telles que Medical, automobile, électronique, et biens de consommation. Comprendre ces processus permet aux fabricants de sélectionner la méthode la plus efficace et la plus rentable pour leurs applications spécifiques, Assurer des produits de silicone de haute qualité et fiables.