Pengeluar Acuan Getah Silikon

LGDSilicone Parts ialah pembekal terkemuka bagi bahagian yang dihasilkan menggunakan proses pengacuan getah silikon. LGDSilicone menawarkan penyelesaian komprehensif untuk aplikasi Silicone Rubber Molding yang direalisasikan

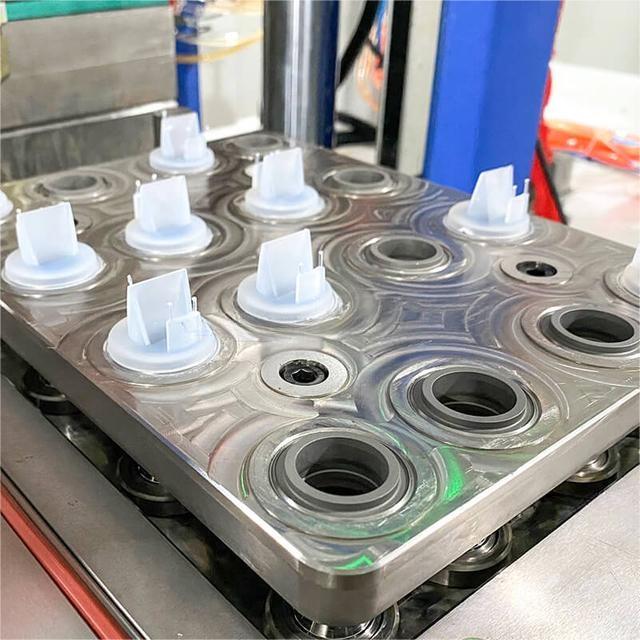

Perkhidmatan Pengeluar Acuan Silikon

Sebagai peneraju dan perintis dalam industri, kita tahu acuan getah silikon dalam dan luar. kami mengambil pendekatan sistem yang lengkap dan teknologi canggih, automasi dan perancangan kualiti adalah asas.

Di Lgdsilicone, Jurutera dan pasukan teknikal kami bekerjasama untuk menentukan penyelesaian terbaik yang akan memenuhi objektif produk pelanggan kami, tambah nilai, dan itu akan mengikut piawaian tinggi dalaman kita sendiri untuk kualiti, kecekapan, dan produktiviti.

Kami menawarkan portfolio penuh perkhidmatan, termasuk: Reka bentuk & Prototaip, Pengeluaran dan Operasi Sebaris Nilai Ditambah.

Acuan Getah Silikon Keupayaan Pengeluaran Lain

LGDSilicone menawarkan beberapa pilihan untuk Keupayaan Pengeluaran Acuan Getah Silikon

Pengacuan Mampatan

Silicone Rubber Compressing Molding ialah proses Compression Molding dengan Silicone Rubber sebagai bahannya.

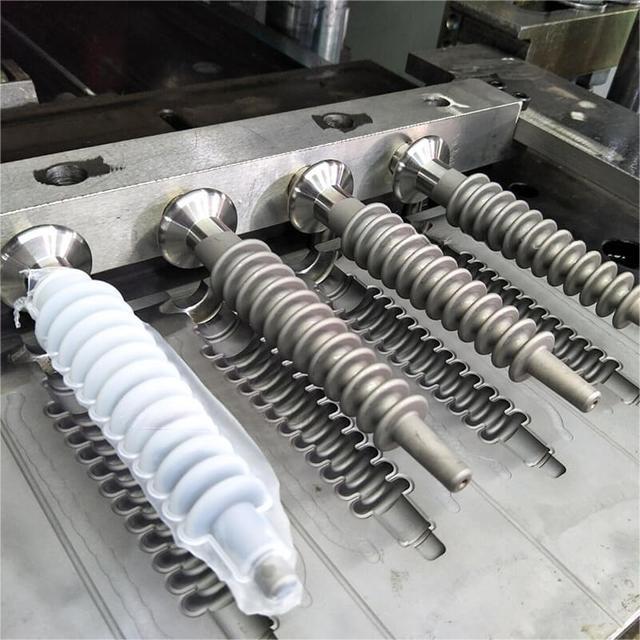

Pengacuan Suntikan LSR

Pengacuan Suntikan LSR ialah proses menyuntik Getah Silikon Cecair ke dalam mesin pengacuan untuk membuat bahagian.

Pengacuan Suntikan HCR

Proses pengacuan suntikan silikon HCR biasanya melibatkan pemanasan bahan mentah dan menyuntiknya di bawah tekanan tinggi ke dalam acuan.

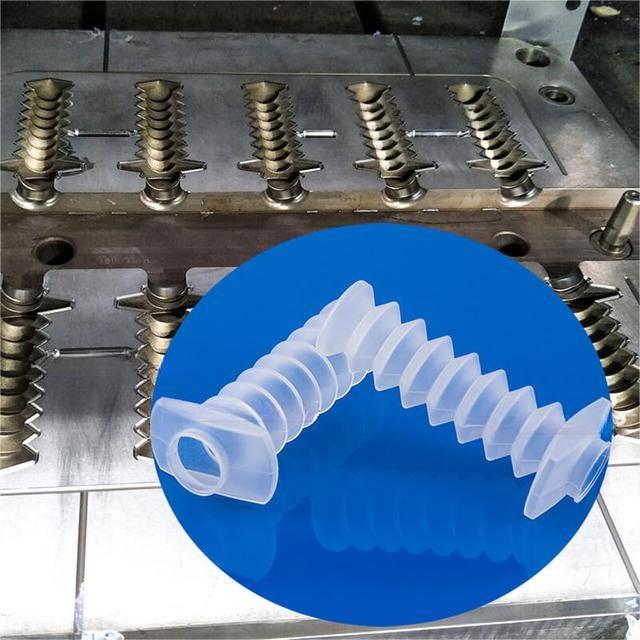

Penyemperitan Silikon

Penyemperitan silikon ialah proses di mana silikon dipaksa melalui acuan berbentuk untuk menghasilkan panjang yang terbentuk secara berterusan

Silikon Overmolding

Pengacuan berlebihan silikon melibatkan meletakkan bahagian logam atau plastik ke dalam rongga acuan dan memanaskannya untuk menyembuhkannya

Kalender Silikon

Kalender silikon ialah proses mekanikal yang digunakan untuk mengeluarkan kepingan seragam yang diperbuat daripada getah silikon

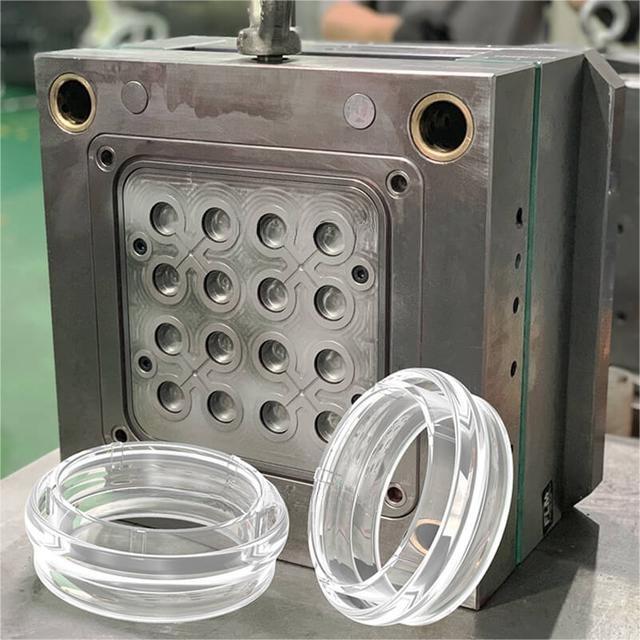

Acuan Produk Silikon

Proses Pengeluaran Pengacuan Silikon

Semua fasa proses pembangunan produk silikon, termasuk reka bentuk produk, perkakas ketepatan, pembuatan, dan pemenuhan, berlangsung di LGDSilicone di bawah satu bumbung.

1. Pilih bahan durometer dan silikon yang sesuai

Kami boleh mengesyorkan bahan silikon optimum dengan menilai dengan betul keperluan pelanggan kami. Bahan yang paling praktikal akan dipilih berdasarkan struktur dan fungsi produk, persekitaran aplikasi, prestasi, keperluan ujian keselamatan, dan bajet pelanggan.

2. Penggabungjalinan dan pengadunan bahan silikon

3. Memotong / Mengkosongkan

Bahan silikon selepas pengadunan akan dikumpulkan dalam gulungan besar yang ditutup dengan filem untuk mengelakkan habuk atau kotoran. Ia kemudiannya akan dipotong menjadi kepingan oleh mesin pemotong automatik. Panjang dan lebar kepingan akan dikawal mengikut berat bahagian silikon yang akan dibentuk. Pengosongan silikon memudahkan pengendali acuan kami untuk menimbang bahan semasa pengeluaran acuan silikon.

4. Letakkan bahan silikon pada acuan alat panas dan timbangkannya.

5. Pengacuan pemvulkanan bahagian silikon

Bahan silikon akan sembuh sepenuhnya di bawah suhu tinggi dan tekanan daripada mesin pengacuan pemvulkanan, kemudian bahagian silikon terbentuk. Jabatan acuan kami dilengkapi dengan 8 mesin pemvulkan vakum automatik berketepatan tinggi yang boleh digunakan untuk menghasilkan lebih banyak bahagian silikon berprestasi tinggi. Mesin acuan kami yang canggih, ditambah dengan pengendali mahir kami, menyediakan kapasiti dan fleksibiliti untuk membentuk berkualiti tinggi, bahagian silikon volum tinggi dalam peroid pendek.

6. Demolding

Mesin pengacuan pemvulkanan akan secara automatik melegakan tekanan selepas silikon sembuh sepenuhnya, membenarkan kakitangan pengacuan mengeluarkan kepingan acuan silikon dengan menarik keluar acuan alat. Bahan mentah akan diletakkan semula untuk kitaran pemvulkanan berikut.

7. Deflash

Kilat Silikon – Merupakan kepak nipis bahan di garisan perpisahan tempat acuan terbelah. Disebabkan oleh kelikatan rendah bahan silikon dan tekanan pengacuan yang tinggi semasa pemanasan dan pengawetan, Bahan silikon bertekanan akan mengalir ke setiap ruang acuan alat. Denyar boleh diminimumkan dengan reka bentuk yang menarik dan perkakasan yang lebih baik serta berat bahan yang tepat semasa pengeluaran acuan pemvulkan. Denyar akan dikeluarkan terutamanya dengan tangan, deflashing kriogenik juga boleh digunakan untuk beberapa kes.

Di mana anda mencari bahagian silikon?

LDGSilicone membekalkan pelbagai bahagian acuan Getah Silikon tersuai. Bahagian ini boleh didapati dalam produk yang digunakan dalam pelbagai industri, termasuk automotif, Aeroangkasa,Alat memasak, Kehidupan Sains (seperti produk perubatan/penjagaan kesihatan/penjagaan bayi), dan Mainan dan aplikasi khas.

Pusat Pengukuran

3D Sistem Pengukuran

Ujian Penebat

Lelasan RCA

Ujian Tork

Ujian Tegangan

Ujian Kakisan

Ujian Suhu H-L

Ujian XRF untuk RoHS

Soalan Lazim Acuan Silikon Tersuai

Apakah peralatan yang diperlukan untuk pengacuan suntikan?

- 5 bertahun-tahun pengalaman pengacuan suntikan plastik dan pengalaman pemprosesan

- Pengalaman dengan peralatan muat/punggah/pembungkusan robotik amat diutamakan

- Pengalaman berkaitan persediaan tangan dengan mesin pengacuan suntikan plastik, kren, pelbagai alatan tangan, pengawal suhu, tekan gerudi, mengetuk lengan, memilih dan meletakkan robot, dan lain-lain.

Bolehkah anda silikon acuan suntikan?

Pengacuan suntikan getah silikon cecair adalah satu proses untuk menghasilkan lentur, bahagian tahan lama dalam jumlah yang tinggi. Getah silikon cecair ialah silikon terawat platinum ketulenan tinggi dengan set mampatan rendah, kestabilan yang hebat dan keupayaan untuk menahan suhu panas dan sejuk yang melampau sesuai untuk pengeluaran bahagian, di mana kualiti tinggi adalah satu kemestian. Disebabkan sifat termoset bahan, pengacuan suntikan silikon cecair memerlukan rawatan khas,

Apa yang dibuat dengan pengacuan suntikan?

Berapakah kos acuan silikon?

Kos acuan atau alat silikon bergantung pada keperluan produk anda. Sebelum anda boleh mendapatkan harga, anda mesti mempunyai reka bentuk kejuruteraan. Laminar Industries boleh membantu menyelaraskan sebut harga untuk anda. Sila hubungi kami di sales@lgdsilicone.com dan kami berbesar hati untuk membantu menunjukkan anda ke arah yang betul.