Toonaangevende fabrikant van siliconenproducten & Leveranciers

Uw siliconenonderdelen- en productexpert met tientallen jaren ervaring

- One-Stop-diensten

- Volledige certificeringen

- Kant-en-klare oplossing

- Tientallen jaren ervaring

Voordelen van onze oplossingen voor siliconenproduct

Gratis monster beschikbaar

Er zijn gratis voorbeelden beschikbaar om de details te controleren.

Gegarandeerde doorlooptijd

Een stabiele doorlooptijd van de buurt 15 Dagen zijn gegarandeerd.

Professionele team

Professioneel personeel om een efficiënte communicatie te garanderen.

Snelle reactie

We beloven dat we op elke vraag binnenin reageren 12 uren.

Aangepaste siliconenproducten

One-stop-leverancier van idee tot markt voor siliconenproducten voor consumenten en oplossingen voor het vormen van siliconen

Siliconenonderdelen en productprocessen

Om ervoor te zorgen dat onze goederen kosteneffectief zijn, we hebben een gestructureerd productiesysteem gebouwd om samen te werken met de QA en R&D-afdelingen.

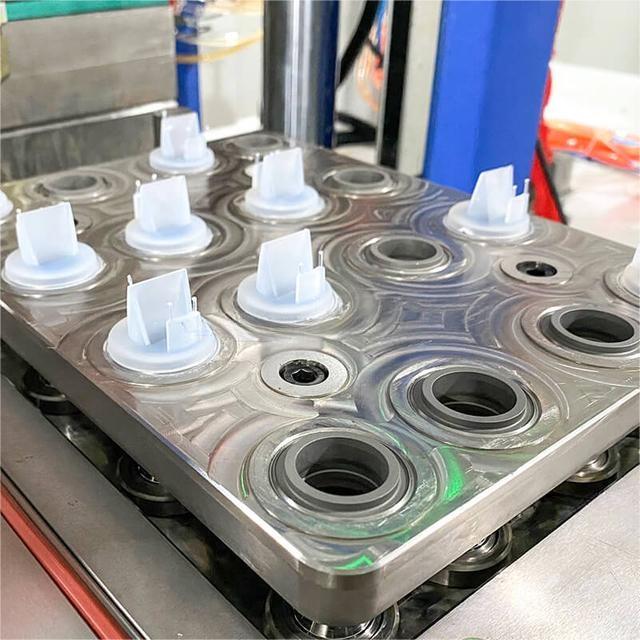

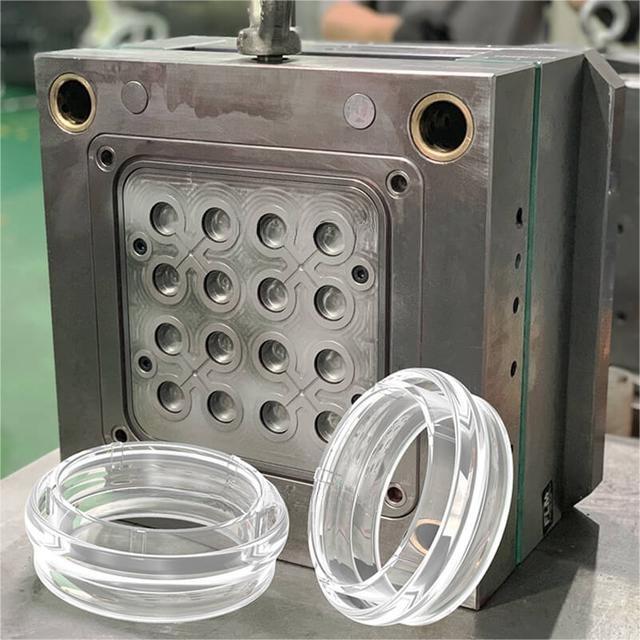

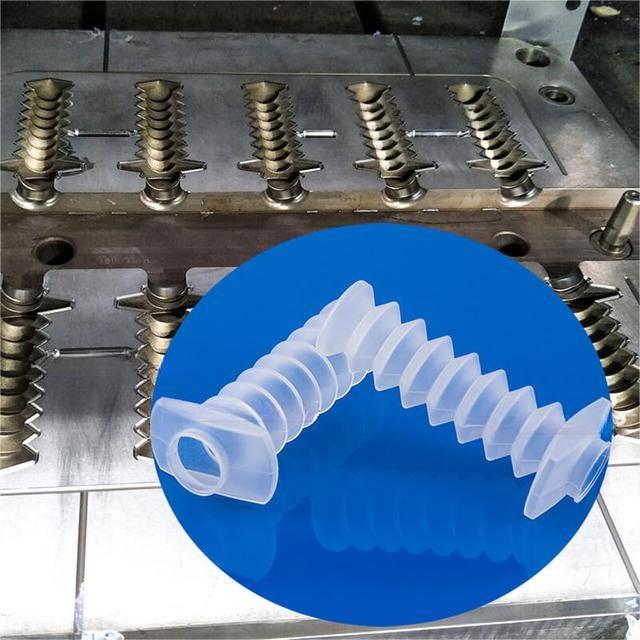

Vormen maken

Voor elk siliconenproduct, onze vormafdeling ontwerpt en maakt de matrijs, zorgen voor een hoge productie en hoge kwaliteit.

Mengen

Meng de grondstoffen met kleur- en vulkanisatiemiddelen en voorkom voortijdige uitharding. rol met plasticfolie om besmetting te voorkomen.

Persvormen

De stripmaterialen worden in de mallen geplaatst, gevolgd door de automaat, waar ze verwarmd zullen worden, ingedrukt, en vervolgens geproduceerd.

Ontflitsen

In de delashingworkshop, alle producten ondergaan het afbraamproces, en werknemers zorgen ervoor dat het productoppervlak glad is.

Secundaire vulkanisatie

De spullen gaan naar de ovenwerkplaats, waar ze zullen doorbrengen 4 uur onder 200°C en worden gebruikt voor temperatuurregistratie.

Afdrukken, snijden, en spuiten

We offer post-processing services for the product's surface, inclusief bedrukking, snijden, talkpoeder spuiten, en andere processen.

Vorm van siliconenproducten

Waar vind je productonderdelen van siliconen ?

LDGSilicone levert een breed scala aan op maat gemaakte siliconenrubber vormdelen. Deze onderdelen zijn te vinden in producten die in een breed scala van industrieën worden gebruikt, inclusief automobiel, Ruimtevaart,Kookgerei, levenswetenschappen (zoals medische/gezondheidszorg/babyverzorgingsproducten), en speelgoed en speciale toepassingen.

Aangepaste productie van siliconenproducten

Met diensten variërend van ontwerpondersteuning, productieprototypes en pilotruns, tot hoge precisie, grootschalige productie van vloeibare siliconenrubberonderdelen en componenten, ons doel is om een topfabrikant van siliconenproducten en een zakenpartner waarop u kunt vertrouwen die consequent superieure service en innovatie biedt, hoogwaardige siliconen gegoten oplossingen.

Waarom kiezen voor LGD-siliconen?

Als leider en pionier in de branche, we kennen siliconenrubber van binnen en van buiten. We volgen een complete systeembenadering en geavanceerde technologie, Automatisering en kwaliteitsplanning zijn de basis.

Wereldwijde leverancier van siliconenvormproducten

Op aanvraag aangepast

Alle siliconenrubberproducten kunnen worden aangepast aan uw behoeften.

CE, FDA-goedgekeurd

Al onze producten hebben FDA- en CE-goedkeuring. You don't have to be concerned about safety.

Milieuvriendelijke materialen

Onze artikelen zijn gemaakt met milieuvriendelijke componenten en procedures.

Geweldige ondersteuning

Een groep met kennis van zaken, opgeleide medewerkers die goed Engels spreken, helpen u verder.

Vormmogelijkheden van siliconenproducten

LGDSilicone biedt verschillende opties voor de productiemogelijkheden van siliconenrubberafgietsels

Persvormen

Siliconenrubber compressiegieten is het proces van compressiegieten met siliconenrubber als materiaal.

LSR-spuitgieten

LSR-spuitgieten is het proces van het injecteren van vloeibaar siliconenrubber in de vormmachine om het onderdeel te maken.

HCR -spuitgieten

HCR -siliconen spuitgietproces omvat meestal het verwarmen van de grondstof en het injecteren van onder hoge druk in een schimmel.

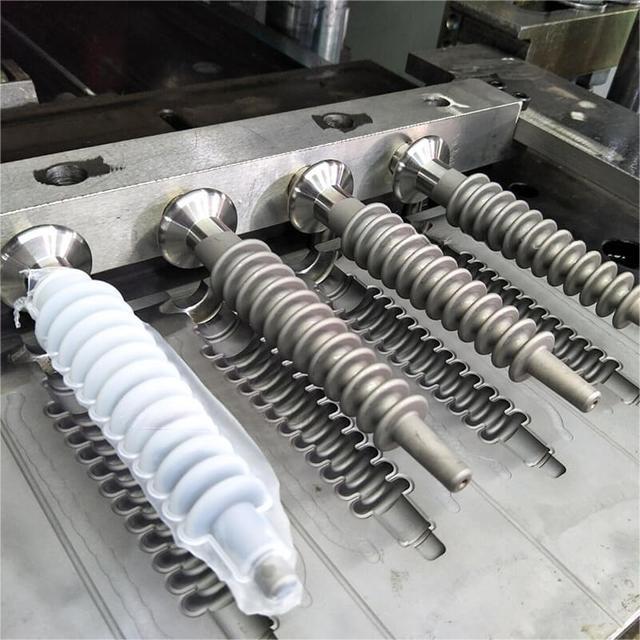

Siliconen extrusie

Siliconenextrusie is het proces waarbij siliconen door een gevormde matrijs worden geperst om een ononderbroken gevormde lengte te produceren

Siliconen overmolding

Bij het omspuiten met siliconen wordt een metalen of plastic onderdeel in een vormholte geplaatst en verwarmd om het uit te harden

Siliconen kalanderen

Siliconenkalanderen is een mechanisch proces dat wordt gebruikt om uniforme vellen van siliconenrubber te vervaardigen

Ons kwaliteitsproces

LGDSilicone biedt verschillende opties voor de productiemogelijkheden van siliconenrubberafgietsels

LGDSilicone biedt de uitzonderlijk hoogwaardige processen die nodig zijn voor producten in de gezondheidszorg en medische apparatuur.

SIMTEC is ISO9001, ISO 13485, en we beschikken over een van de laagste defectpercentages in onze branche.

Met onze focus op de sterk op maat gemaakte productie van gegoten siliconen medische onderdelen, wij maken onze QA-processen op maat.

3D Meetsysteem

Trekproef

Isolatietest

Corrosietest

Veelgestelde vragen over siliconenproducten

Welke siliconenproducten verkopen wij in de groothandel?

Wij groothandel een reeks siliconenproducten. Babyvoeding & tandjes krijgen, siliconen huisdierbenodigdheden, siliconen kookgerei, en andere siliconenproducten vormen de belangrijkste divisies van onze groothandelsgoederen. Wij gebruiken uitsluitend BPA-vrij, voedselveilige materialen voor onze producten.

Waar wordt siliconenrubber voor gebruikt??

Siliconenrubber kan gemakkelijk worden uitgehard en gegoten om producten zoals auto- en elektronische afdichtingsmiddelen en pakkingen te produceren, banden, kabels, industriële mallen, voedsel schimmels, artistieke replicaties, speelgoed en speeltoestellen, mallen, reproducties en bakvormen. En door de jaren heen, de siliconenproducten die we hebben vervaardigd, zijn inmiddels uitgegroeid tot veel van deze producten.

Heeft u een leverancier van siliconenproducten nodig??

U heeft meer nodig dan alleen een leverancier van siliconenproducten, u heeft een leverancier nodig die u volledige oplossingen kan bieden, van ontwerpfase tot vrachtverzending, en breid zelfs meer service uit om uw bedrijf een boost te geven. Onze taken en verantwoordelijkheid zijn niet alleen om u te voorzien van hoogwaardige siliconenproducten.

Wat is het verschil tussen vaste siliconen en vloeibare siliconen?

Vaste siliconen worden vooral gebruikt voor vormproducten, voornamelijk de productie van vershouddeksels, bakvormen, servies, siliconen bakvormen, en andere producten. Vloeibare siliconen worden voornamelijk gebruikt voor het extruderen van producten, voornamelijk de productie van rietjes, fopspenen, baby bijtringen, cosmetica, en andere producten.

Maakt u alleen gereedschapsmallen of ook eindproducten van siliconen??

Wij zijn One-Stop-Shop voor op maat gemaakte siliconenprojecten, van mallen tot eindproducten. Wij bieden ondersteuning gedurende het gehele traject, van productontwikkeling tot after-sales service.

Als u op zoek bent naar een nieuwe siliconenfabriek om een mal te maken voor uw volgende siliconenproduct of een siliconenfabrikant die een complete service biedt (gietvorm + productie en misschien verpakking), LGDSilicone is uw ideale partner die u zoekt.

Onze uiteindelijke massaproductiedienst voor siliconenproducten omvat de productie van gietstukken, merkdiensten, en op maat gemaakte verpakkingsoplossingen.

Bent u een siliconenfabrikant of handelsbedrijf??

Wij zijn een 100% eigen siliconenfabriek die zich bezighoudt met op maat gemaakte siliconenproducten voor 15 jaren.

Met een eigen gereedschapmakerij en vormfabriek, wij bieden de volledige ontwikkelingscyclus van siliconenproducten onder één dak. Door de volledige ontwikkelingscyclus van siliconenproducten onder één dak aan te bieden- van het ontwerpen van onderdelen & van het bouwen van mallen tot het starten van de volledige productie- u verkleint de risico's van het werken met meerdere leveranciers, de time-to-market verbeteren & lagere kosten.

Het staat onze partners vrij om een bezoek aan onze fabriek te plannen en getuige te zijn van ons siliconenproductieproces in actie.

Waarvoor worden de gegoten siliconenonderdelen gebruikt??

Deze gegoten siliconen onderdelen zijn breed om hittebestendigheid isolerend te maken, zoals instrumentatiebehuizingen, spoelvormers, schakelaars, aansluitblokken en nog veel meer. U kunt deze vormdelen dus naar eigen behoefte gebruiken. Wij vervaardigen de producten voor verschillende soorten en texturen op basis van de nieuwste technologie en kwaliteitsmaterialen.

Wees op de hoogte van alle gebeurtenissen

Siliconen versus TPE

-

Gepost door

Frank

- 0 opmerkingen

Silicone vs TPU:Een uitgebreide vergelijking

-

Gepost door

Frank

- 0 opmerkingen

Siliconenvulkanisatie: Van fundamentals tot applicaties

-

Gepost door

Frank

- 0 opmerkingen

Siliconen persgieten

-

Gepost door

Frank

- 0 opmerkingen

Het productieproces van siliconenproducten

-

Gepost door

Frank

- 0 opmerkingen

Siliconentypen en verschillen

-

Gepost door

Frank

- 0 opmerkingen

Gids voor LSR-spuitgieten

-

Gepost door

Frank

- 0 opmerkingen

Vloeibaar siliconenrubber gietproces

-

Gepost door

Frank

- 0 opmerkingen

Siliconen kennis – Waar is siliconen van gemaakt?

-

Gepost door

Frank

- 0 opmerkingen

Thermoplastisch elastomeer: De ultieme gids

-

Gepost door

Frank

- 0 opmerkingen

Siliconen extrusie: De ultieme gids in 2023

-

Gepost door

Frank

- 0 opmerkingen

Overdracht gieten: Wat is transfergieten en hoe werkt het?

-

Gepost door

Frank

- 0 opmerkingen