Silicone Rubber Molding Manufacturer

LGDSilicone Parts is a leading provider of produced parts using the silicone rubber molding process. LGDSilicone offers comprehensive solutions for Silicone Rubber Molding applications realized

Silicone Molding Manufacturers Service

Como líder e pioneira na indústria, we know silicone rubber molding inside and out. adotamos uma abordagem de sistemas completos e tecnologia avançada, automação e planejamento de qualidade são a base.

At Lgdsilicone, Our engineers and technical team work together to determine the best solution that will meet our customers’ product objectives, add value, and that will measure-up to our own internal high standards for quality, efficiency, and productivity.

We offer a full portfolio of services, Incluindo: Design & Prototyping, Production and Value-Added Inline Operations.

Silicone Rubber Molding Other Production Capabilities

LGDSilicone oferece várias opções para capacidades de produção de moldagem de borracha de silicone

Moldagem por compressão

A moldagem por compressão de borracha de silicone é o processo de moldagem por compressão com borracha de silicone como material.

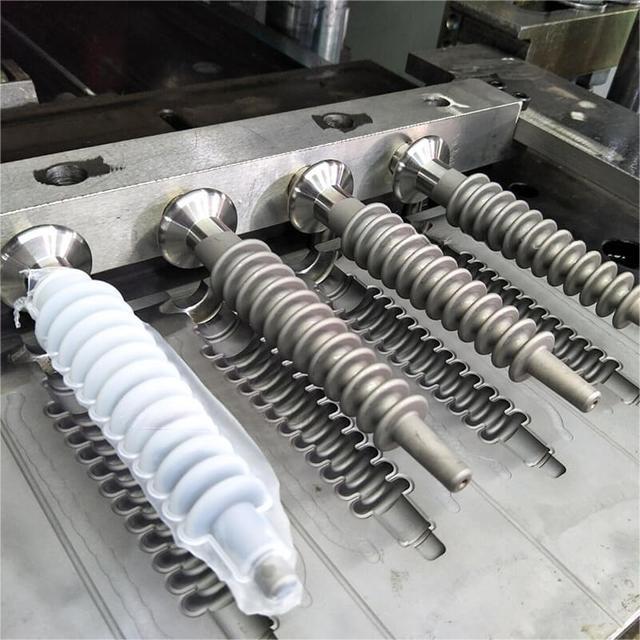

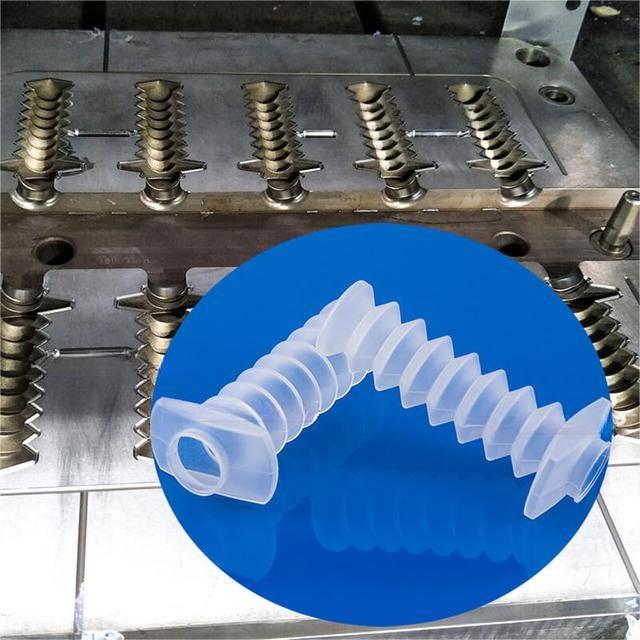

LSR Moldagem por Injeção

A Moldagem por Injeção LSR é o processo de injeção de Borracha de Silicone Líquida na máquina de moldagem para fazer a peça.

Moldagem por Injeção HCR

O processo de moldagem por injeção de silicone HCR normalmente envolve aquecer a matéria-prima e injetá-la sob alta pressão em um molde.

Extrusão de Silicone

A extrusão de silicone é o processo no qual o silicone é forçado através de uma matriz moldada para produzir um comprimento formado contínuo

Sobremoldagem de Silicone

A sobremoldagem de silicone envolve colocar uma peça de metal ou plástico em uma cavidade do molde e aquecê-la para curá-la

Calandragem de Silicone

A calandragem de silicone é um processo mecânico usado para fabricar folhas uniformes feitas de borracha de silicone

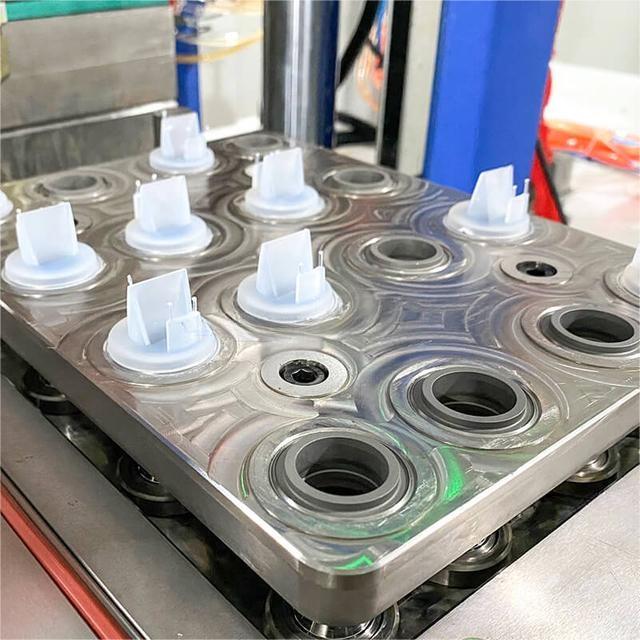

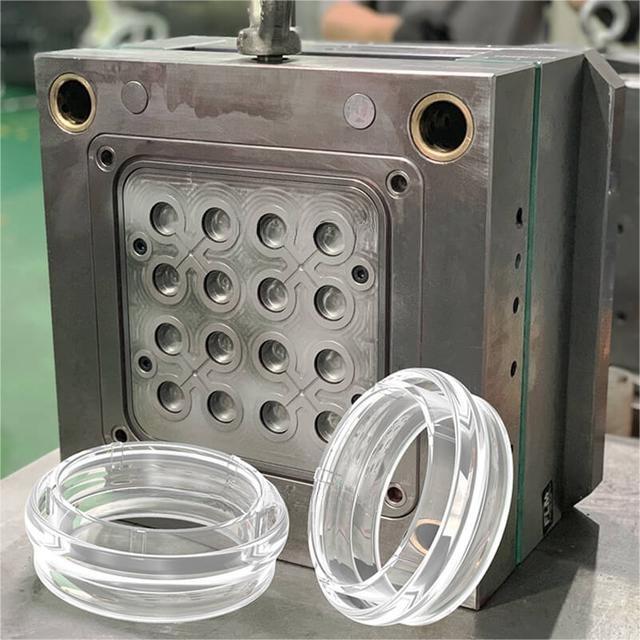

Molde De Produtos De Silicone

The Silicone Moulding Production Process

All phases of the silicone product development process, including product design, precision tooling, manufacturing, and fulfillment, take place at LGDSilicone under one roof.

1. Select the appropriate durometer and silicone material

We can recommend the optimum silicone material by properly assessing the needs of our customers. The most practical material will be chosen based on the product’s structure and function, the application environment, performance, safety test requirements, and the customer’s budget.

2. Silicone material compounding and blending

3. Cutting / Blanking

![]()

Silicone material after blending will be collected in large rolls covered with film to prevent dust or dirt. It then will be cut into slices by an automatic cut machine. The slices’ length and width will be controlled according to the silicone part’s weight to be molded. Silicone blanking makes it easier for our molding operators to weight the material during silicone molding production.

4. Put the silicone substance on the hot tool mold and weigh it down.

5. Silicone part vulcanization molding

![]()

Silicone material will be fully cured under high temperature and pressure from vulcanizing molding machine, then the silicone parts are formed. Our molding department is equiped with 8 high precision automatic vacuum vulcanizing machines which can be used to craft more high performance silicone parts. Our sophisticated molding machines, coupled with our skilled operators, provide the capacity and flexibility to mould high-quality, high-volume silicone parts in short peroid.

6. Demolding

![]()

The vulcanizing molding machine will automatically relieve pressure after the silicone is fully cured, allowing molding personnel to remove the silicone-molded pieces by pulling out the tool mold. The raw material will be repositioned for the following vulcanization cycle.

7. Deflash

![]()

Silicone Flash – Is a thin flap of material at the parting line where the mold splits. Due to the low viscosity of silicone material and high molding pressure during heating and curing, The pressurized silicone material will flow to every spaces of tool mold. Flash can be minimized with favorable designs and better tooling and accurate material weight during vulcanizer molding production. Flash will be removed mainly by hands, cryogenics deflashing can also be applicated for some cases.

Where do you find silicone parts?

LDGSilicone fornece uma ampla gama de peças de moldagem de borracha de silicone personalizadas. Essas peças podem ser encontradas em produtos utilizados em uma ampla gama de indústrias, incluindo automotivo, Aeroespacial,Utensílios de cozinha, Ciências da Vida (tais como produtos médicos/saúde/cuidados com o bebê), e Brinquedos e aplicações especiais.

O Centro de Medição

3D Sistema de Medição

Teste de isolamento

Abrasão RCA

Teste de Torque

Teste de Tração

Teste de Corrosão

Teste de temperatura H-L

Teste de XRF para RoHS

Custom Silicone Mold FAQs

What equipment is needed for injection molding?

- 5 years of plastics injection molding set-up and processing experience

- Experience with robotic load/unload/packing equipment is highly preferred

- Hand-on set-up related experience with plastic injection molding machines, cranes, various hand tools, temperature controllers, drill press, tapping arms, pick and place robots, etc.

Can You injection mold silicone?

Injection molding of liquid silicone rubber is a process to produce pliable, durable parts in high volume. Liquid silicone rubber is a high purity platinum cured silicone with low compression set, great stability and ability to resist extreme temperatures of heat and cold ideally suitable for production of parts, where high quality is a must. Due to the thermosetting nature of the material, liquid silicone injection molding requires special treatment,

What is made by injection molding?

How much does a silicone mold cost?

The cost of a silicone mold or tool depends on the requirements of your product. Before you can get pricing, you must have an engineered design. Laminar Industries can help streamline the quote for you. Pleas contact us at sales@lgdsilicone.com and we’ll be happy to help point you in the right direction.