シリコンラバーモールディングメーカー

LGDSilicone Partsは、シリコンラバーモールディングプロセスを使用して生産された部品の大手プロバイダーです. LGDSiliconeは、シリコンラバーモールディングアプリケーションのための包括的なソリューションを提供しています

シリコンモールディングメーカーサービス

業界のリーダー、パイオニアとして, 内外のシリコンゴムモールディングを知っています. 私たちは完全なシステムアプローチと高度な技術を採用しています, 自動化と品質計画が基盤.

Lgdsiliconeで, エンジニアとテクニカルチームが協力して、お客様の製品目標を達成する最良のソリューションを決定する, 値を追加します, そして、それは品質のための私たち自身の内部の高い基準を測定します, 効率, そして生産性.

サービスの完全なポートフォリオを提供しています, 含む: デザイン & プロトタイピング, 生産および付加価値インライン操作.

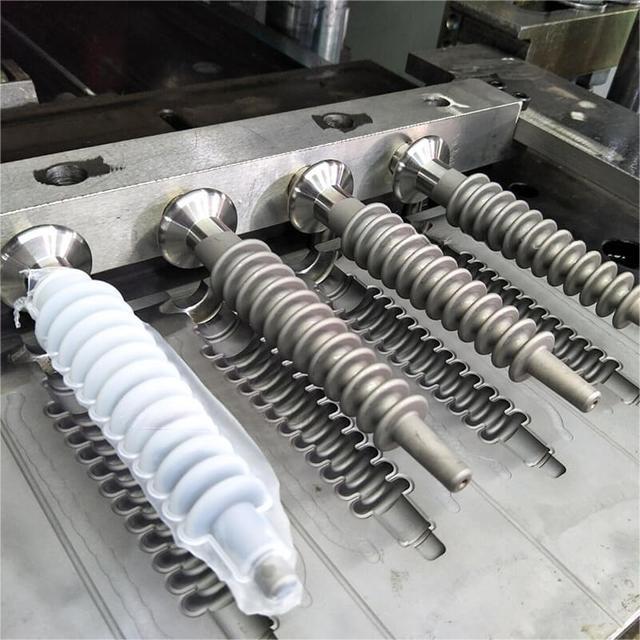

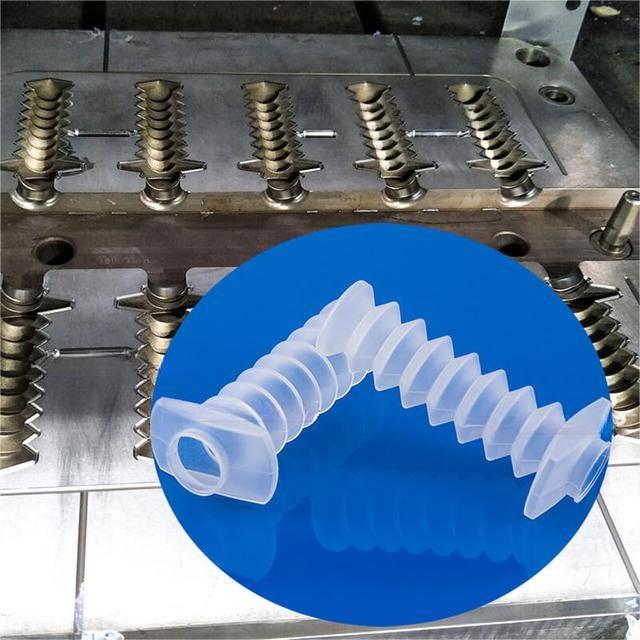

他の生産能力を成形するシリコンゴム製

LGDSilicone は、シリコーン ゴム成形生産能力にいくつかのオプションを提供します

シリコーンのオーバーモールド

シリコーンのオーバーモールドでは、金属またはプラスチック部品を金型キャビティに配置し、加熱して硬化させます。

シリコーンカレンダー

シリコーンカレンダー加工は、シリコーンゴム製の均一なシートを製造するために使用される機械的プロセスです

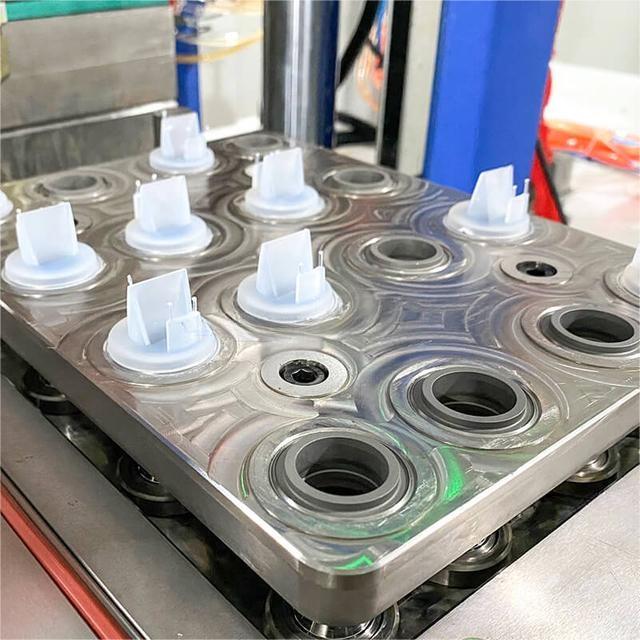

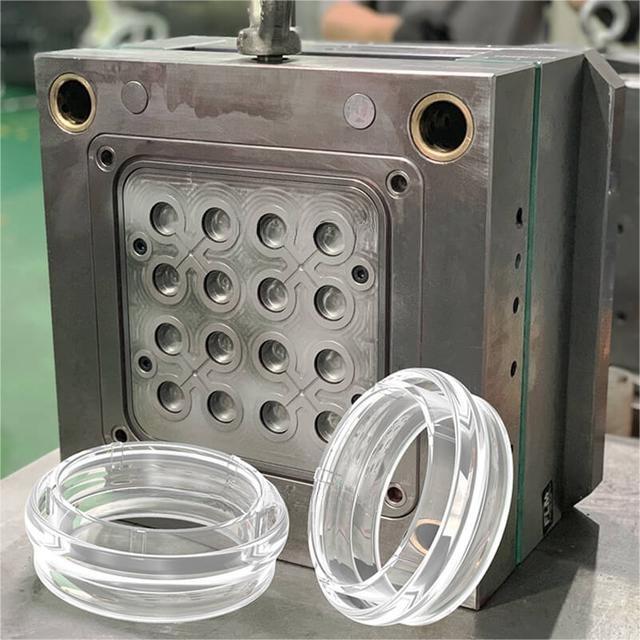

シリコーン製品の金型

シリコーン成形生産プロセス

シリコン製品開発プロセスのすべての段階, 製品設計を含む, 精密ツール, 製造, そして充足, 1つの屋根の下でLGDSiliconeで行われます.

1. 適切なデュロメーターとシリコン材料を選択します

お客様のニーズを適切に評価することで、最適なシリコン素材をお勧めします. 最も実用的な素材は、製品の構造と機能に基づいて選択されます, アプリケーション環境, パフォーマンス, 安全テストの要件, 顧客の予算.

2. シリコン材料の複合とブレンド

3. 切断 / ブランキング

ブレンド後のシリコン素材は、ほこりや汚れを防ぐためにフィルムで覆われた大きなロールで収集されます. その後、自動カットマシンによってスライスにカットされます. スライスの長さと幅は、成形されるシリコン部分の重量に応じて制御されます. シリコンブランキングにより、シリコーン成形生産中に成形オペレーターが材料の重量を簡単にすることができます.

4. シリコン物質をホットツールの型に置き、それを計量します.

5. シリコン部品加硫の成形

シリコン材料は、高温で完全に硬化し、硫化する成形機からの圧力をかけます, その後、シリコン部品が形成されます. 私たちの成形部門には装備されています 8 より高性能シリコン部品を作成するために使用できる高精度自動真空硫化機械. 洗練された成形機, 熟練したオペレーターと相まって, 高品質の成形能力と柔軟性を提供します, 短いペロイドの大量のシリコン部品.

6. demolding

シリコンが完全に硬化した後、加硫化成形機は自動的に圧力を緩和します, 工具型を引き出すことで、成形担当者がシリコン成形の部分を取り除くことができます. 原材料は、次の加液サイクルのために再配置されます.

7. デフラッシュ

シリコンフラッシュ - 金型が分割されている別れのラインの材料の薄いフラップです. シリコン材料の粘度が低いため、加熱および硬化中の成形圧力が高いため, 加圧されたシリコン材料は、ツール型のあらゆるスペースに流れます. フレッシュを最小限に抑えることができ、良好なデザインと、より優れたツーリングと、加硫の成形生産中に正確な材料重量. フラッシュは主に手によって削除されます, 極低温デフラシングも場合によっては適用できます.

シリコン部品はどこにありますか?

LDGSilicone は、幅広いカスタム シリコーン ゴム成形部品を提供しています。. これらの部品は、さまざまな業界で使用される製品に使用されています。, 自動車を含む, 航空宇宙,調理器具, 生命科学 (医療/ヘルスケア/ベビーケア製品など), および玩具および特殊用途.

測定センター

3D 測定システム

絶縁試験

RCA摩耗

トルク試験

引張試験

腐食試験

H-L温度試験

RoHS の XRF テスト

カスタムシリコン金型FAQ

射出成形に必要な機器?

- 5 プラスチックの長年の射出成形セットアップと処理体験

- ロボットロード/アンロード/梱包装置の経験が非常に好まれます

- プラスチック射出成形機でのハンドオンセットアップ関連エクスペリエンス, クレーン, さまざまなハンドツール, 温度コントローラー, ドリルプレス, 腕をタッピングします, ロボットを選んで配置します, 等.

射出金型シリコンを射出できますか?

液体シリコンゴムの射出成形は、柔軟性のあるものを生成するプロセスです, 大量の耐久性のある部品. 液体シリコンラバーは、低純度プラチナ硬化シリコンで、低い圧縮セットがあります, 極端な温度に抵抗する優れた安定性と能力は、部品の生産に理想的な理想的なものです, 高品質が必須です. 材料の熱硬化性のため, 液体シリコン射出成形には、特別な治療が必要です,

射出成形によって作られているもの?

シリコーンの金型の費用はいくらですか?

シリコン型またはツールのコストは、製品の要件に依存します. 価格設定を取得する前に, エンジニアリングデザインが必要です. 層状産業は、あなたの引用を合理化するのに役立ちます. 嘆願してください sales@lgdsilicone.com そして、私たちはあなたを正しい方向に向けるのを喜んで助けます.