Leading Silicone Product Manufacturer & Suppliers

Your Silicone Parts And Product Expert with Decades of Experience

- One-Stop Services

- Full Certifications

- Turnkey Solution

- Decades of Experience

Benefits from Our Silicone Product Solutions

Free Sample Available

Free samples are available for you to check the details.

Guaranteed Lead Time

A stable lead time of around 15 days is guaranteed.

Professional Team

Professional personnel to ensure efficient communication.

Quick Response

We promise to respond to any question within 12 hours.

Custom Silicone Products

One-Stop Supplier From Idea To Market For Consumer Silicone Products And Silicone Molding Solutions

Silicone Parts And Product Processes

To make sure that our goods are cost-effective, we have built a structured production system to collaborate with the QA and R&D departments.

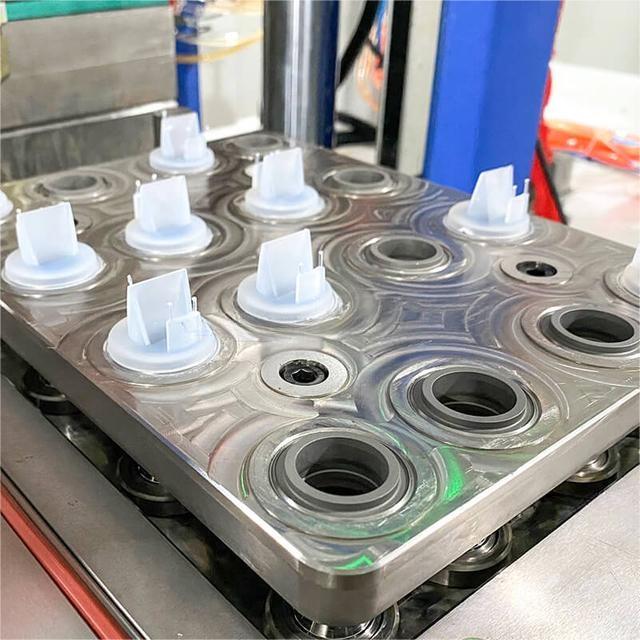

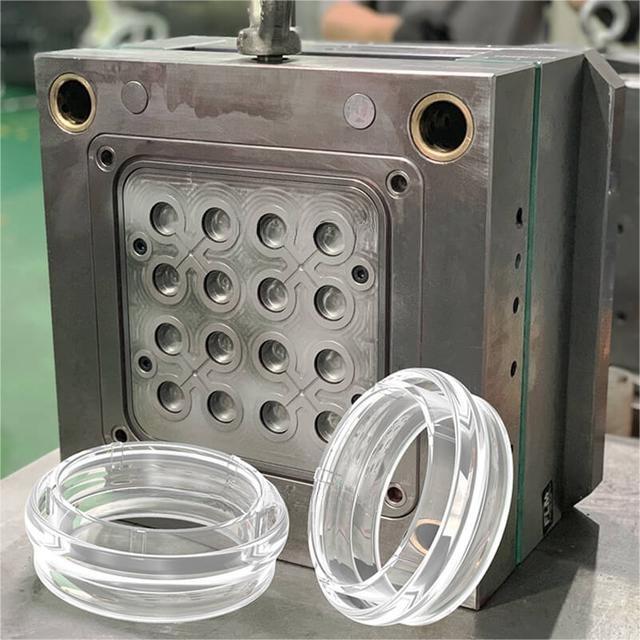

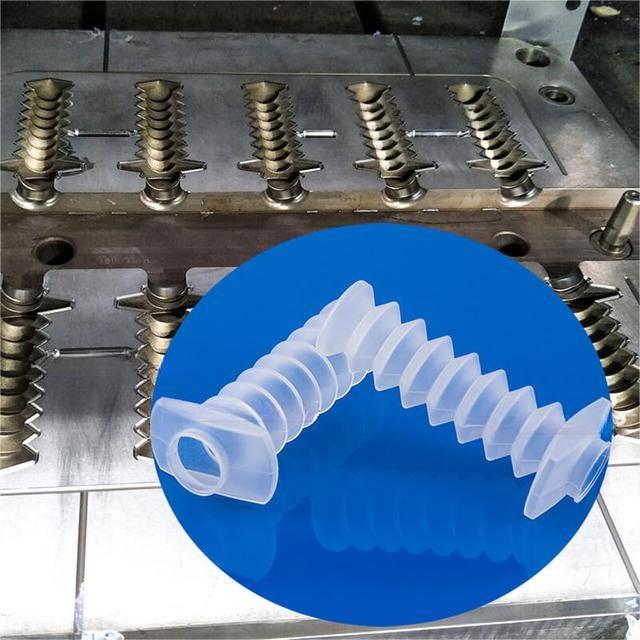

Mold Making

For each silicone product, our molding department designs and creates the mold, ensuring high production and high quality.

Mixing

Mix the raw materials with colorant and vulcanizing agents and avoid premature curing. roll with plast films to avoid contamination.

Compression Molding

The strip materials will be placed in the molds, followed by the machine, where they will be heated, pressed, and then produced.

Deflashing

In the delashing workshop, all products will go through the burring process, and workers will make sure the product surface is smooth.

Secondary Vulcanization

The items will go into the oven workshop, where they will spend 4 hours under 200°C and be used for temperature recording.

Printing, Sliting, and Spraying

We offer post-processing services for the product's surface, including printing, slitting, talc powder spraying, and other processes.

Mold Of Silicone Products

Where do you find product parts of silicone ?

LDGSilicone supplies a wide range of custom Silicone Rubber molding parts. These parts can be found in products used in a wide array of industries, including automotive, Aerospace,Cookware, life sciences (such as medical/healthcare /baby care products), and Toy and special applications.

Customized Silicone Product Molding Manufacturing

With services ranging from design support, production prototypes and pilot runs, to high precision, large-scale Liquid Silicone Rubber parts and components production, our goal is to remain a top Silicone product manufacturer and a business partner you can rely on to consistently provide superior service and innovative, high quality silicone molded solutions.

Why Choose LGD Silicone?

As a leader and pioneer in the industry, we know silicone rubber molding inside and out. we take a complete systems approach and advanced technology, automation and quality planning are the foundation.

Global Supplier of Silicone Molded Products

Customized on Demand

All silicone rubber products can be customised to meet your needs.

CE, FDA Approved

All of our products have FDA and CE approval. You don't have to be concerned about safety.

Eco-Friendly Materials

Our items are made with eco-friendly components and procedures.

Great Support

A group of knowledgeable, trained employees who speak good English will help you.

Silicone Products Molding Capabilities

LGDSilicone offers several options for Silicone Rubber Molding Production Capabilities

Compression Molding

Silicone Rubber Compressing Molding is the process of Compression Molding with Silicone Rubber as the material.

LSR Injection Molding

LSR Injection Molding is the process of injecting Liquid Silicone Rubber into the molding machine to make the part.

HCR Injection Molding

HCR silicone injection molding process typically involves heating the raw material and injecting it under high pressure into a mold.

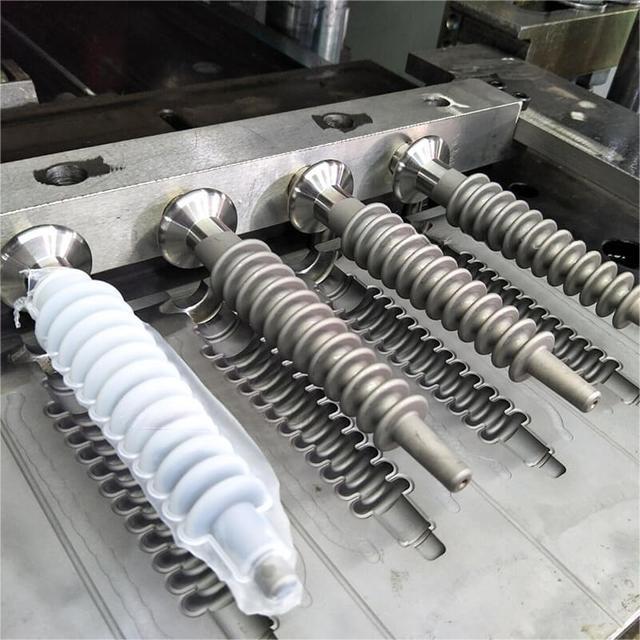

Silicone Extrusion

Silicone extrusion is the process in which silicone is forced through a shaped die in to produce a continuous formed length

Silicone Overmolding

Silicone over-molding involves placing a metal or plastic part into a mold cavity and heating it to cure it

Silicone Calendering

Silicone calendering is a mechanical process used to manufacture uniform sheets made of silicone rubber

Our Quality Process

LGDSilicone offers several options for Silicone Rubber Molding Production Capabilities

LGDSilicone provides the exceptionally high quality processes required for healthcare and medical device products.

SIMTEC is ISO9001, ISO 13485, and we boast one of the lowest defect rates in our industry.

With our focus on the highly customized production of molded silicone medical parts, we tailor our QA processes.

3D Measurement System

Tensile Test

Insulation Test

Corrosion Test

Silicone Product FAQs

What silicone products do we wholesale?

We wholesale a series of silicone products. Baby feeding & teething, silicone pet supplies, silicone cookware, and other silicone products are the major divisions of our wholesale goods. We exclusively utilize BPA-free, food-grade materials for our products.

What is silicone rubber used for?

Silicone rubber is readily cured and moulded to produce items such as automotive and electronic sealants and gaskets, tyres, cables, industrial moulds, food moulds, artistic replications, toys and play equipment, moulds, reproductions and bakeware. And over the years, the silicone products we have manufactured have grown to include many of these.

Do you need a silicone product supplier?

You need more than just a silicone product supplier, you need a supplier who can give you full solutions from design step to cargo shipment, and even extend more service to help boost your business. Our tasks and responsibility are not just to provide you with quality silicone goods.

What is the difference between solid silicone and liquid silicone?

Solid silicone is mainly used for molded products, mainly producing fresh-keeping lids, bakeware, tableware, silicone bakeware, and other products. Liquid silicone is mainly used for extruding products, mainly producing straws, pacifiers, baby teethers, cosmetics, and other products.

Are you making only tooling molds or final silicone products as well?

We are One-Stop-Shop for custom silicone projects from molds to final products. We offer support throughout the entire process, from product development to after-sales service.

If you are searching for a new silicone factory either to make a mold for your next silicone product or a silicone manufacturer that provides a complete service (mold + production and maybe packing), LGDSilicone is your ideal partner you are looking for.

Our final silicone products mass production service includes molding production, branding services, and custom packing solutions.

Are you a silicone manufacturering factory or trading company?

We are a 100% self-owned silicone factory dealing with custom silicone products for 15 years.

With an in-house tooling shop and molding plant, we offer the complete silicone product development cycle under one roof. By offering the complete silicone product development cycle under one roof- from designing parts & building molds to launching into full-blown production- you will reduce the risks of working with multiple vendors, improve time to market & lower costs.

Our partners are free to schedule a visit to our factory and witness our silicone manufacturing process in action.

What are the molded silicone parts used for?

This molded silicone parts are wide to make heat resistance insulating such as instrumentation housing, coil formers, switches, terminal blocks and many more. So you can use these molding parts as per your needs. We are manufacturing the products for various types and textures based on the latest technology and quality material.

Be Aware of All Events

Silicone VS TPE

-

Posted by

Frank

- 0 comments

Silicone VS TPU:A Comprehensive Comparison

-

Posted by

Frank

- 0 comments

Silicone Vulcanization: From Fundamentals to Applications

-

Posted by

Frank

- 0 comments

Silicone Compression Molding

-

Posted by

Frank

- 0 comments

Silicone Products Manufacturing Process

-

Posted by

Frank

- 0 comments

Silicone Types and Differences

-

Posted by

Frank

- 0 comments

Guide To LSR Injection Molding

-

Posted by

Frank

- 0 comments

Liquid Silicone Rubber Molding Process

-

Posted by

Frank

- 0 comments

Silicone Knowledge – What Is Silicone Made of?

-

Posted by

Frank

- 0 comments

Thermoplastic Elastomer: The Ultimate Guide

-

Posted by

Frank

- 0 comments

Silicone Extrusion: The Ultimate Guide in 2023

-

Posted by

Frank

- 0 comments

Transfer Molding: What Is Transfer Molding and How Does It Work?

-

Posted by

Frank

- 0 comments